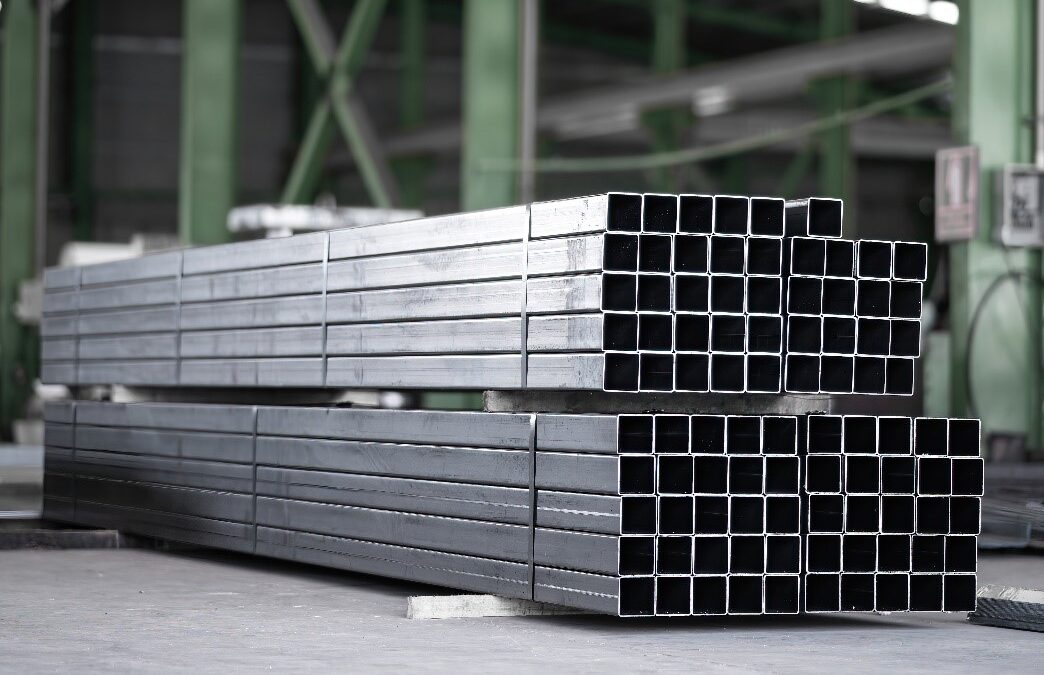

Square tubes are fabricated hollow metal products that are common in various applications such as general fabrication, construction, frames, gates, railings, and more. They’re made from different lightweight yet durable metals and may come in two types: welded and seamless square tubes. Square tubes are designed to withstand pressure and structural load.

Learning about the differences between a welded and seamless square tube can help you pick the right type for your project. Here are some of the differences between the two:

- Welded Square Tubes

Welded tubes are manufactured from a metal sheet that is rolled into itself and then welded along the length of the tube. The welding process may depend on the material of the sheet, its thickness, and the manufacturer’s preference. Once formed, the tube is cut to the desired length, and the excess material is removed.

One great thing about welded square tubes is that they’re more economical to produce than their seamless counterparts. They can also be available in longer lengths. Welded tubes can also be made with thinner walls, making them useful for specific applications. However, they’re often less resistant to corrosion and may contain some impurities from the manufacturing process.

- Seamless Square Tubes

On the other hand, a seamless square tube can be manufactured using several different methods. A popular technique is the rotary piercing process, where a cylindrical billet of metal is drilled through and then heated. This material is then fed through numerous rollers. The outer rollers shape the outside diameter, while the piercer roll forms the inner diameter, allowing for a smoother and more accurate product.

Seamless tubes are known for superior corrosion resistance, higher durability, and pressure rating. It also has a cleaner and smoother finish compared to welded tubes, but they’re more expensive and can be more laborious to produce.

Which Type Is Right for Your Project?

Selecting whether you need seamless square tubes or welded tubes will depend on their intended use. Welded tubes are suitable for applications that do not require heavy load-bearing capacity but will need precise dimensions. They’re also used for more general purposes mainly due to their affordability and easier manufacturing process.

On the other hand, seamless tubes are used for more extreme cases that will require enhanced strength. Their resistance to corrosion and bending makes them ideal for transporting petroleum, gas, water, and other materials. On top of that, seamless tubes also provide additional durability.

Besides steel tubes, we at Whitt Building Supplies can also provide you with the necessary building supplies for your project. We can also provide you with a free estimate within 24 hours. To learn more about our current inventory, contact us and talk to one of our staff members today.

Recent Comments